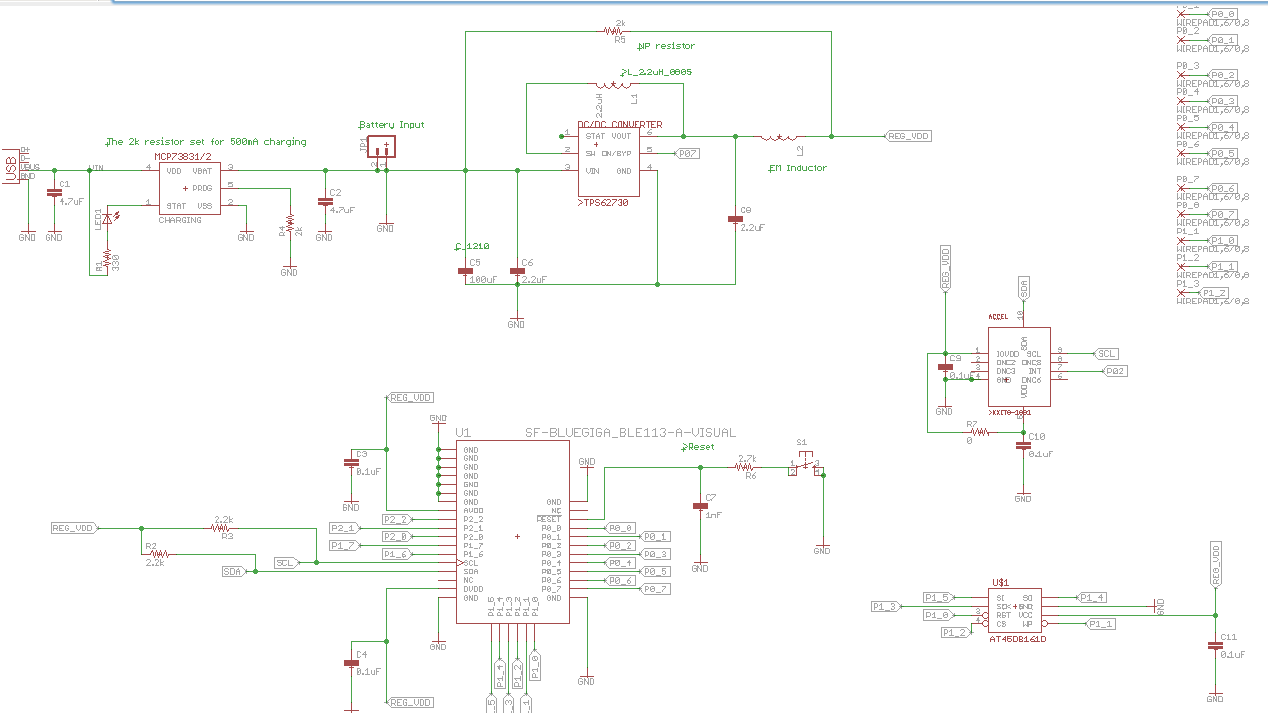

In the past week, we were able to ordered most of the needed hardware, and I was able to use Eagle to start making custom PCB. Eagle has a lot of open source libraries for the hardware we ordered, yet I had to make my own libraries that I could not find online. For example, I made DC/DC buck converter TPS62730, and its footprint size is 1.5mm x 1.05mm, therefore even every little error could be critical. I also made a library for KTIX9 accelerometer that is little bigger the DC buck converter.

However, after talking with TA and Professor Patel, we decided not to use buck converter for two reason, the first one is it is not necessary to DC buck converter to make the system power efficient since the system will be operating with 3.3 V; the second reason the DC buck converter package is QFN, which in not human solderable. It is better off not to use. In conclusion, we will need finalize the both schematic and layout the PCB, and then launch 1x1 scale PCB on printing paper, and check if the parts we order fit into spots.